Executive Summary

Cottage companies and individuals making outdoor gear are often faced with a difficult challenge: With hundreds of specialty technical fabrics available, what fabric should be used in their next project? To answer this question, I create a database of technical outdoor fabric material properties, and formulate a number of use-case based optimization problems to aid gear makers in selecting the best fabric for the job. Finally, I present a material selection tool that can be used to identify the best fabrics for each use-case, and walk through 2 case studies of material selection for ultralight packs.

Background

As an avid backpacker, I've recently fallen down the rabbit-hole of ultralight gear. Over the course of the past few years I've been swapping my equipment out for lighter and lighter gear, and seeing first-hand the benefit of carrying an ultralight pack. The engineer sitting somewhere in my brain loves to optimize, and finding the line between utility and weight has been a fun challenge for me. In my quest to drop weight, I've gotten into sewing my own gear, and I've found a community of like minded individuals in the "Make Your Own Gear" section of BackPackingLight.com. There are nearly 8 million posts in this forum discussing everything from aluminum can stoves to self made dual wall tents, and it seems with enough searching one can find a topic on nearly anything related to homemade ultralight backpacking gear (one recent topic discusses the viability of milkweed fluff as an insulation).

A favorite topic of this forum is the performance of various types of technical fabrics. In the outdoor gear industry, there is a multitude of fabrics available to construct equipment. These fabrics range from inexpensive multi-use ripstop nylon to incredibly expensive specialty Dyneema Composite Fabric (DCF), and nearly anything physically possible in between. For an idea of the number of fabrics available, check out <a href = https://ripstopbytheroll.com/collections/fabric-by-category> Ripstop By The Roll's website </a>. One can find dozens of materials in each of their categories: Wind Resistant, Waterproof, Ultralight, Breathable, Waterproof/Breathable, Downproof and Eco. They also split out fabrics into use categories; There are upwards of 50 different fabrics in the "Pack" section.

With so many options, the BackPackingLight forums are filled with discussions on the merits of all of the options. If you look, you'll find that there's consensus that X-Pac VX07 is more durable than HyperD 300, but not as durable as Cordura 1000d. Likewise, you can find topics on the hydrostatic head of different tarp materials, or the air permeability of wind apparel fabrics. However, there is no central source of information regarding how different fabrics fair in different use cases. The information that is there is scattered about in those 8 million topics; Occasionally, one can find a materials datasheet, or a test report, but there's no way to easily evaluate different fabrics for different use cases.

This poses a problem for gear makers- how should one go about picking fabric for the next project? Often times, the solution to this is to post a new topic along the lines of, "I'm making a backpack, what fabric should I use?". Alternatively, one could go searching through the archives of the forum to find others who have asked similar questions. However, the results of both methods leave much to be desired- while one might find advice on what fabrics to use, often times this advice is not substantiated in any way. Individual anecdotal reports of "I used X, and it worked great" can be useful, but don't give much confidence to an individual who has a different budget/priority/specific use case. What's needed in the BPL community is a centralized source of information for evaluating technical outdoor fabrics.

Formulation

With the tools that I learned in the Spring 2021 session of Probabilistic Design Optimization, I set out to create a central source of information for evaluating technical fabrics in various outdoor equipment use-cases. The solution is the union of two forms; an aggregated database of fabric properties, and an optimization visualization for identifying the best options in a given problem-space.

Materials Database

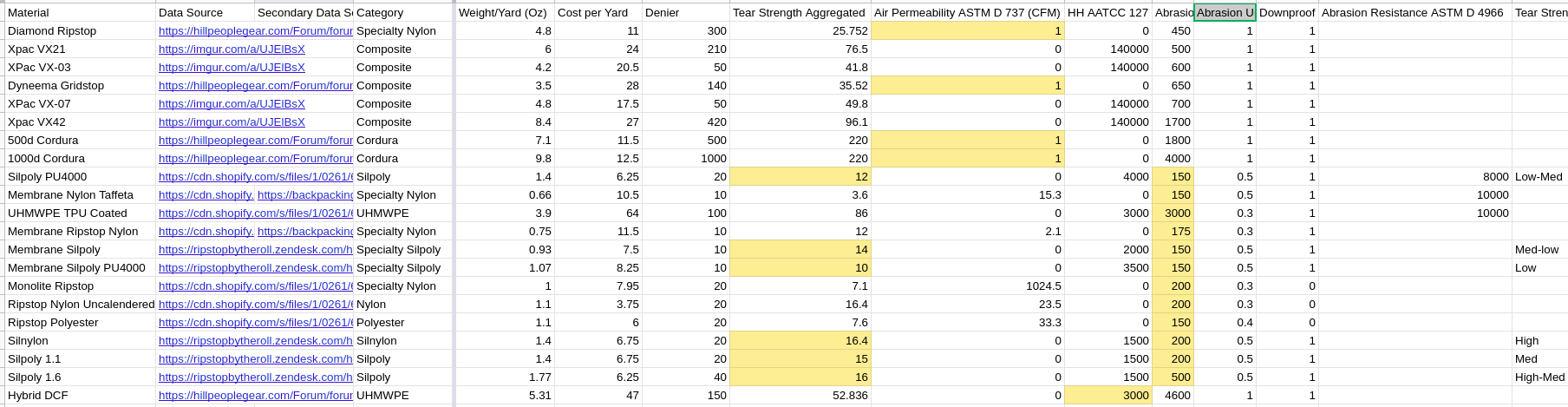

The materials database is a centralized source of information for the fabrics available to the gear maker. I've perused the BPL forums, vendor websites and done a ton of google searches, and aggregated as much information on various fabrics as I could into one single spreadsheet. All information is substantiated by manufacturer provided datasheets or independent BPL user testing with commercial equipment. Nothing is left as anecdotal evidence, nor personal opinion; I've done my best to find as much publicly available information as I can on these fabrics. I've additionally reached out to a couple fabric vendors to see if they have material datasheets that they can disclose, but unfortunately I haven't heard anything back yet.

I developed this database in parallel to determining the optimization equations below, and I've chosen 7 required datapoints on each fabric to include in the database. These datapoints are based on the availability of information that I was able to find, and the different use optimization for each use case. These categories are listed below:

Weight, in Oz/Yard

Cost, in $/Yard

Tear Strength, in N

Air Permeability from ASTM D 737, in CFM

Hydrostatic Head, from AATCC 127, in mm H20

Abrasion Resistance, from ASTM D 3884, in number of cycles

Downproof, Yes/No

Unfortunately, unified testing information seems to be very sparsely available. When testing information even is available, different vendors use different standards, and don't report all testing results across all fabrics. This has made it quite difficult to build up a comprehensive database across all available fabrics. For example, 210D ROBIC Ripstop has no publicly available information anywhere regarding even something as simple as tear strength, and this is the rule, not the exception. This has significantly limited the current database to the fabrics for which I was able to get substantiated information.

Even with these requirements, I had to do a bit of estimation to fill out the database for all of the material information I was able to gather. Thankfully, most of the information didn't require much of a stretch- a fabric that has a greater than zero hydrostatic head may not have a reported air permeability, but one can infer that the air permeability is 0. Likewise, a fabric with a greater than 0 air permeability has a near 0 hydrostatic head. As is explained later, these metrics are mainly used for filtering the database, so exact accuracy isn't a show-stopper. In the database, I've highlighted these values in yellow.

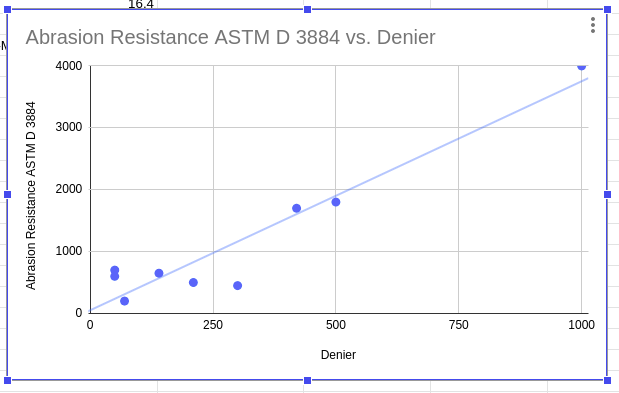

However, one specific metric is crucial, and is generally underreported: Abrasion Resistance. I was only able to find definitive ASTM D 3884 testing information for about half of the materials in the dataset. Abrasion resistance is an optimization objective for many of the types of outdoor gear examined in the second part of this solution, so I needed to find a way to estimate abrasion resistance from the data that I do have. Fortunately, among the samples for which I had data, I was able to find a rough positive correlation between fabric denier (a universally reported fabric datapoint) and abrasion resistance. I extrapolated out the datapoints that I didn't have from a line of best-fit between denier and abrasion resistance, shown in the plot below.

To account for this uncertainty, I added another column to the dataset with the title of "Abrasion Uncertainty". Here I recorded a value of 1 for an abrasion resistance value that I determined from a datasheet, and a value of less than one for any value that was extrapolated from the correlation, with a magnitude given by my confidence in the estimation. I've clearly identified these points in the visualization below as a precaution. I hope to be able to find further definitive sources for this data in the future to remove this uncertainty

The current database can be found here.

If you would like to add fabrics to this database, please contact me with the fabrics you would like to add, and the corresponding datasheet for those fabrics. I hope to continually add more and more fabrics to this database as I find further sources of information.

Optimizations

The second half of this solution is a set of optimizations. I've formulated a number of different fabric use-cases into optimization problems that can be used to evaluate various fabrics in the dataset. Each optimization is a multi-objective optimization, generally looking to minimize cost and weight, while maximizing one or two other criteria specific to the use case. Listed below are the use-cases and their optimization equations, along with a brief discussion on the formulation of each.

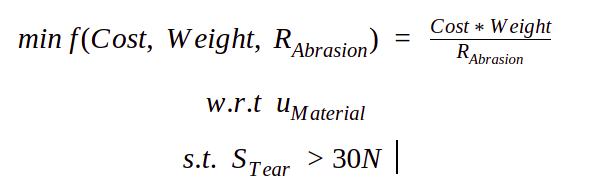

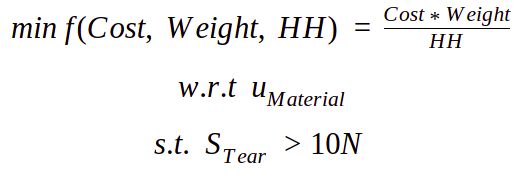

Pack Fabrics, Load Bearing

Packs can be as complicated as the designer wants them to be. Outside pockets, accessories, straps, hipbelts and the like can be made from many different types of material, but the core of the packs are the load bearing panels. These are generally the largest panels in the pack, and make up the majority of the fabric weight in the bag. They also have the highest strength requirement, as they form the structure of the bag and carry the weight of the load in the pack.

To account for the load bearing element of these panels, I've included a constraint of tear strength > 30N. Note that this is not an objective, as we don't care if the tear strength is 32N or 60N; the 30N constraint is enough to ensure that the pack won't tear in half in any normal use, so exceeding this value doesn't help us at all. Instead, the failure case of backpacks is most often wear and tear, so in addition to minimizing cost and weight, I've chosen to maximize abrasion resistance.

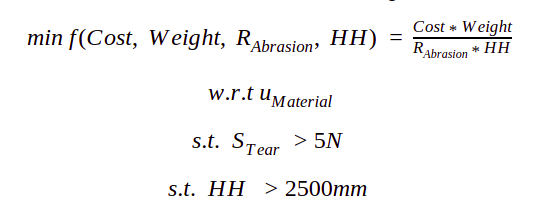

Tarp or Tent Wall Fabrics

Much like packs, Tarp fabrics are subject to a strength constraint; we need them to withstand tight stake-outs and high winds, but only to a certain point. Mostly, we are concerned with increasing waterproofness as much as we can, so the tertiary objective criteria is hydrostatic head.

Groundcloth Fabrics

Groundcloths may be the most abused piece of fabric in a backpacker's kit. They are placed on rocks, dirt, plants, sticks, on snow and even occasionally in puddles, and they're expected to hold up to use every night and maintain complete waterproofness. For this use case, I've chosen to optimize for both hydrostatic head and abrasion resistance. While we're still looking to minimize weight and cost, this seems like a great place to spend a little extra and carry some more ounces to maximize hydrostatic head and abrasion resistance.

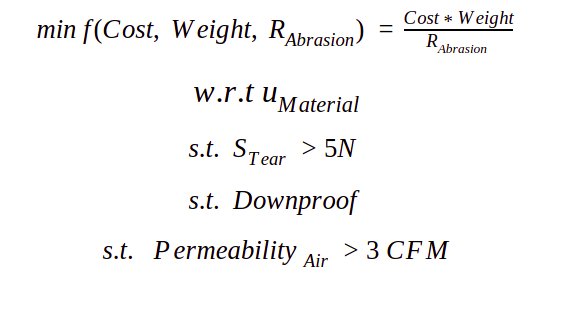

Sleep System (Quilt) & Insulated Apparel Fabrics

For sake of this description, I'll be referring to these fabrics as quilt fabrics, but the same principles apply to sleeping bags, insulated jackets, insulated hats, and so on. These fabrics need to be breathable enough to allow moisture to pass through, but should be downproof, I.E. a tight enough weave that down feathers cannot escape. Quilt fabrics also need to have a high enough tear strength to allow the user to get in and out of the piece of gear without tearing it. Much like the fabrics above, we're looking to maximize abrasion resistance, and minimize cost and weight.

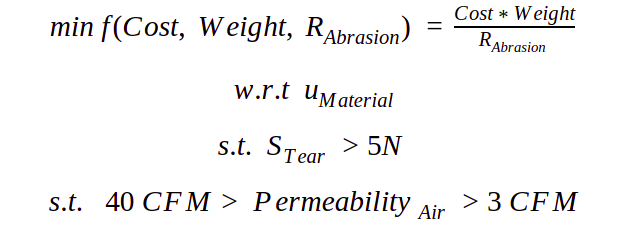

Wind Apparel Fabrics

Finally, wind apparel fabrics are very similar to sleep system fabrics. However, they do not have the downproof criteria, and they must have an air permeability within a range of 3 to 40 CFM to allow moisture to escape but still block the wind.

Results/Visualization

Now, we have a number of objectives by which to evaluate the fabrics in our database. If we're looking for a tarp fabric, we can filter the fabrics by the strength constraint, and then use the optimization objective to determine which fabrics could best suit our use case.

Of course, evaluating an optimization function across dozens of data points isn't something that one can generally do in their head, so I've created a visualization of these 5 optimization problems in the form of material selection charts. These charts can be seen in the interactive plot below, with each chart tab corresponding to one of the described optimization problems.

Categories of fabrics are color coded, and individual fabric names can be seen by mousing over the circle on the chart. Since we're looking at 3 dimensions of optimization, with cost and weight common to all, each optimization chart has a slider on the bottom to move between cost and weight axis. Pareto frontier points have been identified, and are signified by a red bounding circle. Finally, the certainty of the y axis value is shown by the width of the bounding circle. Values with a strong bounding circle signified by a thick outer circle, while uncertain values have a thinner outer circle.

Case Study: Pack Fabrics

Let's say one wanted to make a pack, and needed to go about selecting a fabric for the body panels of said pack. This hypothetical person is budget conscious, and would like to be able to use the pack that they make for a long time. Ultra-low weight is of lesser concern to them.

Looking at the Pack Fabric tab of the material selection chart, with the slider set to "Cost", the 1000d & 500d Cordura and VX07 fabric stand out as low-cost, high abrasion resistance options. Moving to the Weight axis with the slider, we can see that VX07 is the lightest weight of these options by a fair margin. This individual could confidently chose VX07 as their pack fabric.

Now let's consider someone with deep pockets. Cost isn't a barrier to them, but they want whatever they make to last a long time, and have a very low weight. Starting from the weight axis, we can identify Dyneema Gridstop, UHMWPE TPU Coated fabric and Hybrid DCF. Moving to the Cost axis, we can see that Dyneema gridstop is the cheapest, but another look at the weight axis shows UHMWPE TPU Coated fabric to be nearly the same weight and significantly more abrasion resistant. The decision here would come down to the individual's trade off of cost vs weight vs abrasion resistance, but this individual could confidently chose any of these three fabrics.

Conclusion

This solution provides a centralized & clear source of evidence-based guidance for selecting fabrics for varying outdoor use cases. As far as I can tell, outside of the major gear manufacturers, this is a novel approach to a problem that has existed since outdoor technical fabrics were made available to the general public.

The largest insight from this design project has been the acknowledgment of the dearth of information available from vendors on their products. I'm stunned by how little testing data is made public. I'm not sure if this is due to a lack of testing or a desire to keep trade secrets, but for an industry that always seems to be coming out with a "new and better" fabric, there's almost nothing to substantiate those claims. For example, DutchwareGear.com offers one such specialty-made fabric called "Argon." Ripstop by the Roll offers their own, nearly identical line called "Membrane." The Argon 67 and the Membrane .66 oz fabrics are indistinguishable from their product pages, with no more information given other than the weight, Denier and cost of each fabric. What valid reason would one have to chose either fabric without further testing information? Wouldn't it be in the best interest of each vendor to specify testing data as a way to show that their "specialty made" fabric is superior?

In any case, I would love to get 5 samples of each of the hundreds of these fabrics that are sold, and perform an array of ASTM standard tests on them. This testing data would be invaluable to expanding my material database, and providing more points for evaluation in each optimization problem. Barring this, I'd be interested in speaking to the material vendors to ask why they don't provide this data.

As a closing note, I'd like to self-identify as the "budget conscious" individual in the case study. I went through a process of material selection 2 months ago while looking for a backpack fabric, and after pouring over forum posts, anecdotal evidence, and sparse testing data, I eventually chose X-Pac VXO7 as my load bearing panel pack fabric. Although I wish that I had developed this tool before beginning that selection process, it was a great experience to see my material selection substantiated by the tool that I created.